Pedestal plate machine AI vision inspection system

Highlights of the plan: highlights

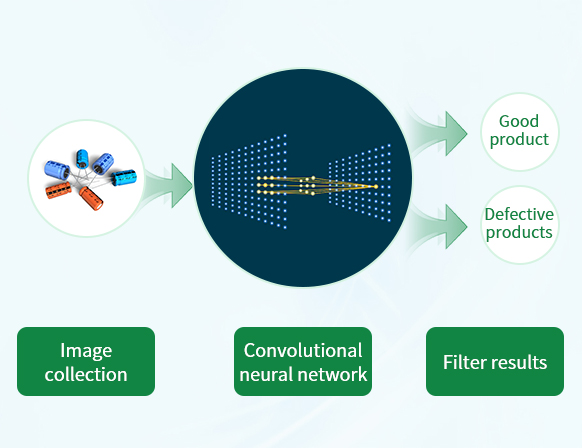

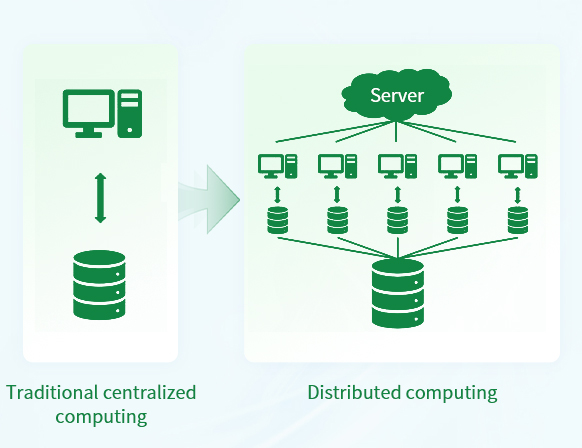

Full-scene intelligent work, replacing the traditional work mode of the back section of the production line of the seat plate machine.。

Based on AI technology, new defects are learned online, with comprehensive coverage of defect types.

One key to import the product model, rapid change of rules, immersive interactive experience.

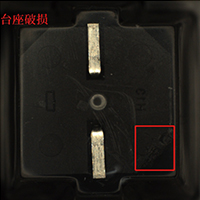

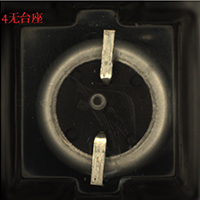

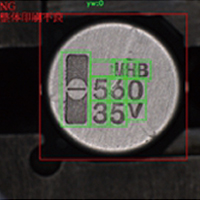

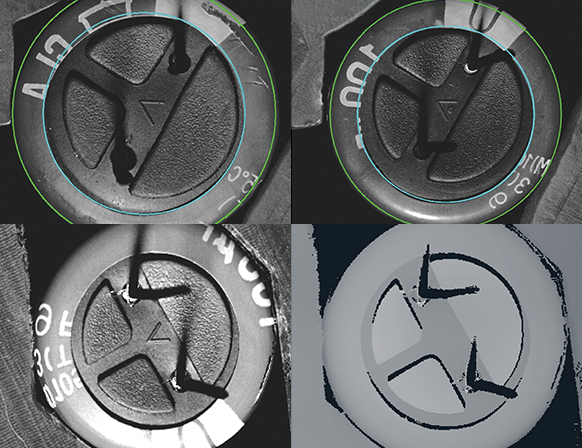

- Defect Detection

- Product Advantages

Defect Detection

Product Advantages