Winding AI vision inspection system

Highlights of the plan: highlights

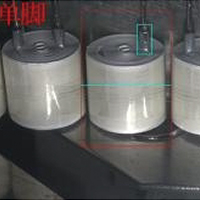

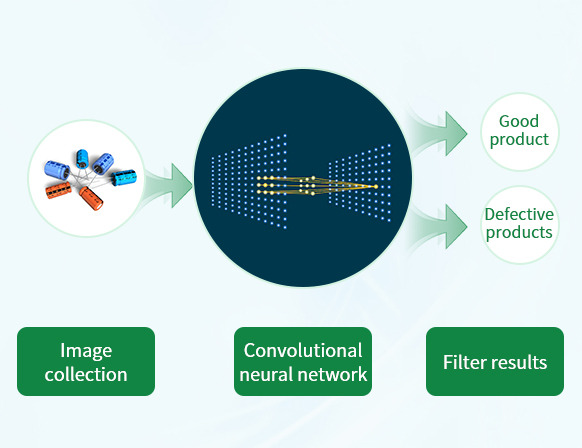

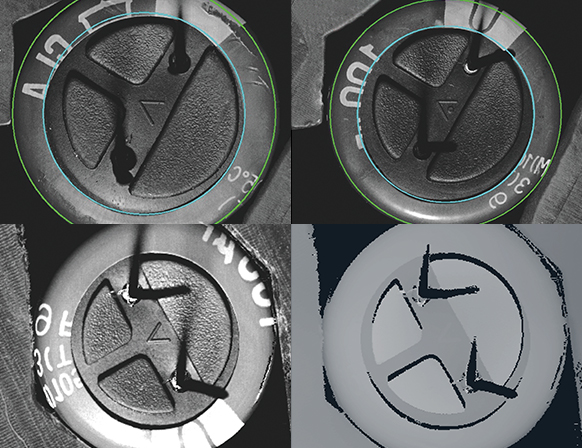

Product core module inspection, from the source to prevent defective products into the back section, saving materials.

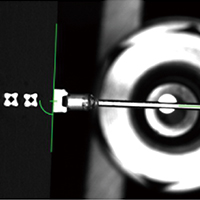

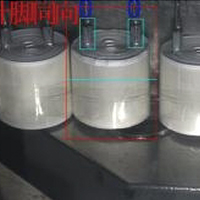

On-line inspection real-time tracking inspection data, abnormal alarm prompts, improve operator efficiency.

Data summary report real-time browsing, tracking the process of each link, help front-end process improvement.

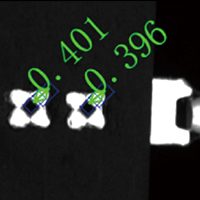

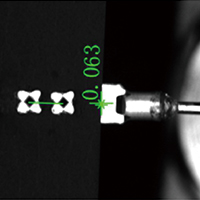

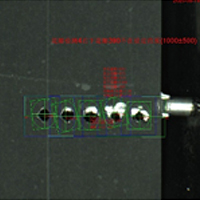

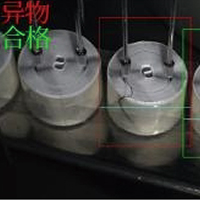

- Defect Detection

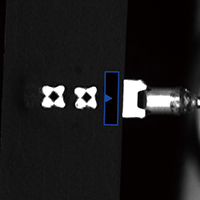

- Product Advantages

Defect Detection

Product Advantages