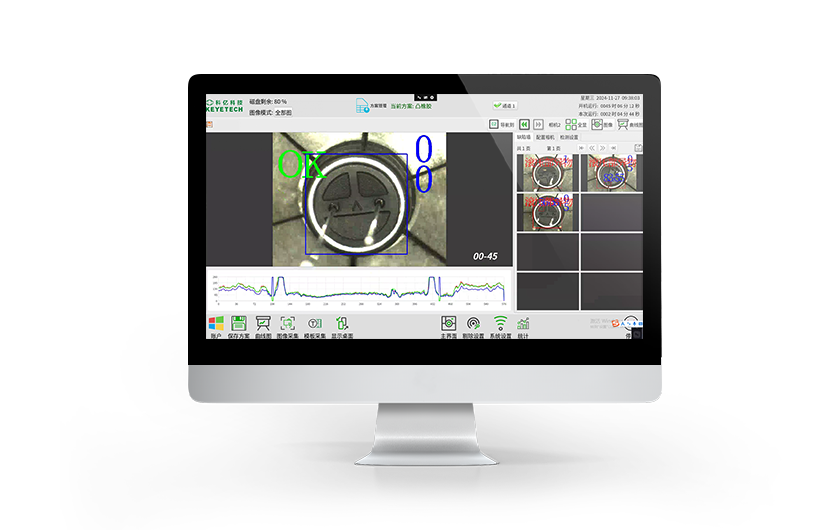

Assemblage AI vision inspection system

Highlights of the plan: highlights

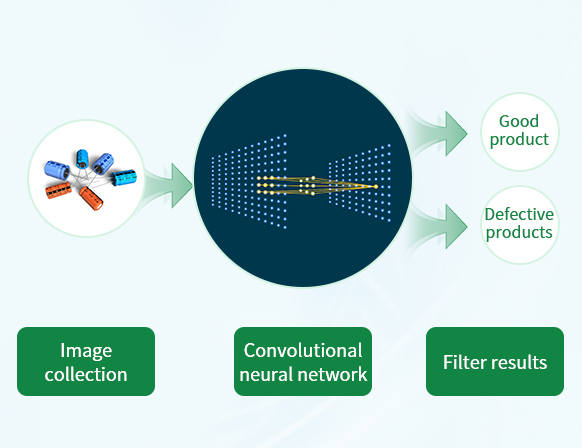

Process quality control, improve the production line pass rate, save materials, reduce costs.

Detect defective products data real-time storage, easy traceability.

Intelligent management of the production line, alarm management system, to prevent the flow of serious defective products.

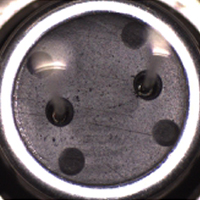

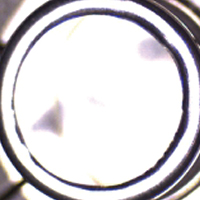

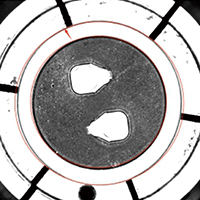

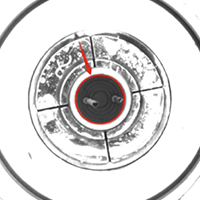

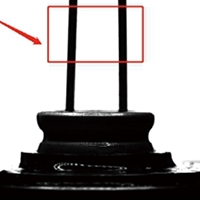

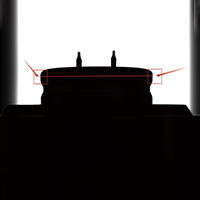

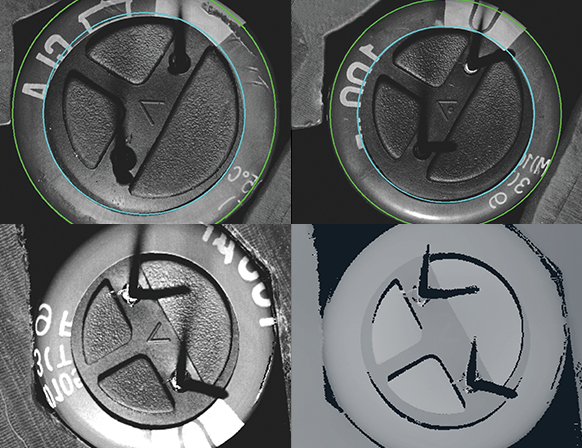

- Defect Detection

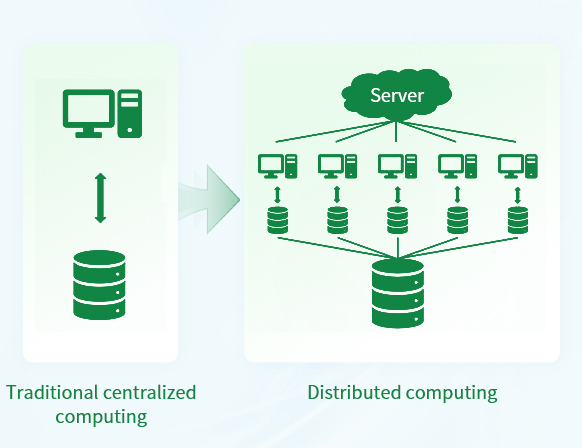

- Product Advantages

Defect Detection

Product Advantages