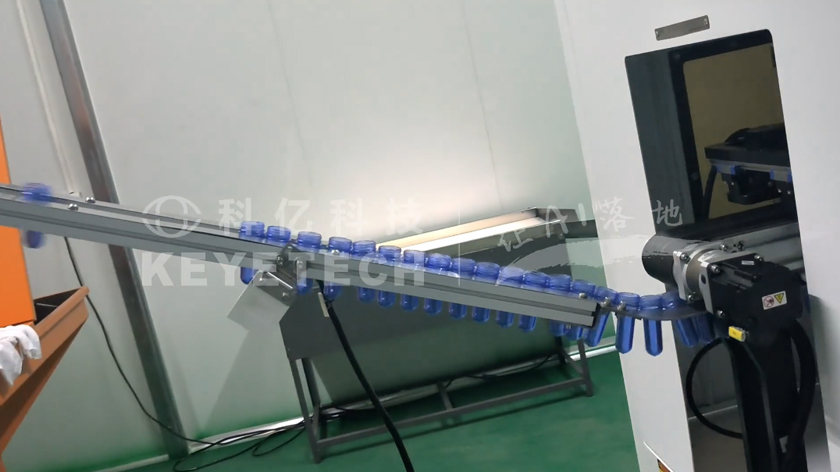

AI bottle preform inspection machine

Inspect 38 ports, 32 ports, etc

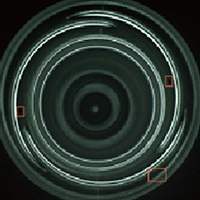

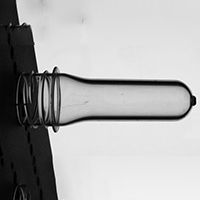

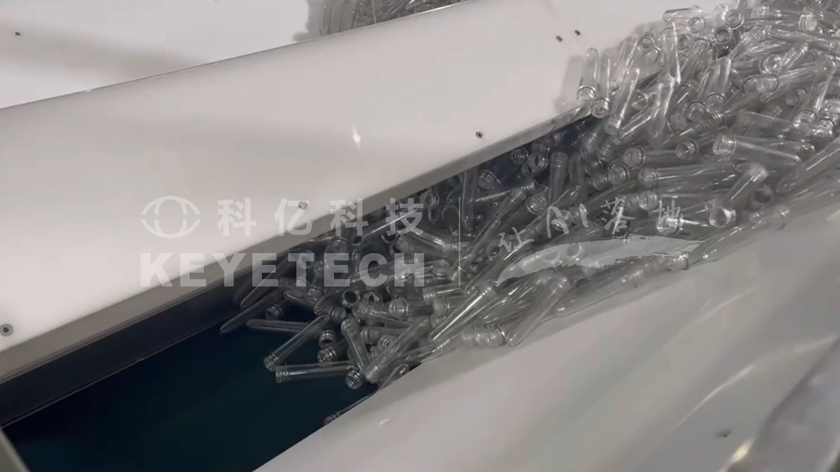

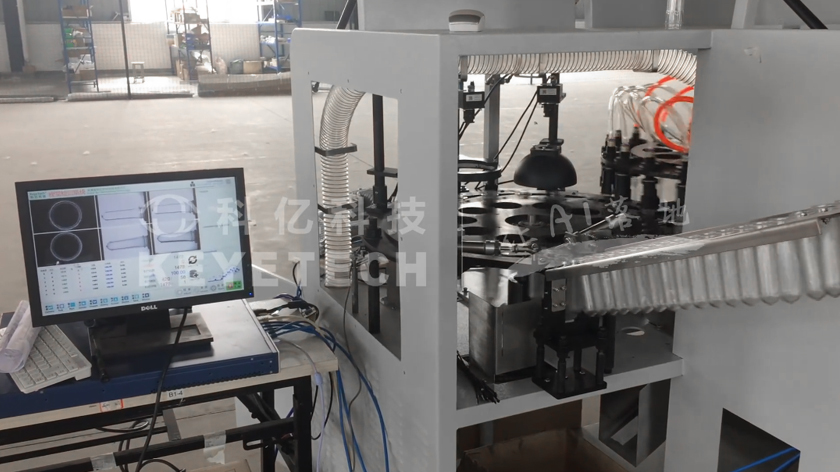

The AI preform inspection machine performs visual defect detection on water preform, beverage preform, oil preform, etc. through processes such as image acquisition, image processing, image annotation, AI algorithm models, and software scheduling. It reject defective products and calculates and divides good products into boxes.

Maximum speed: 400-500 pieces/minute

Detection accuracy: 0.1mm

Detection area: 360 °

- Testing Products

- Defect Detection

- Product Advantages

- Detecting Videos

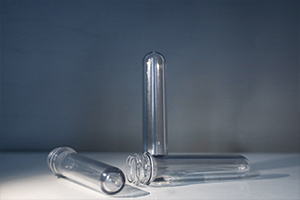

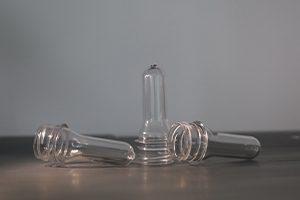

Testing Products

Defect Detection

Product Advantages

Detecting Videos

Previous