What detection mode does the cap detection machine use? Autonomous selection of offline/online mode

Date:2026-01-15 Views:14

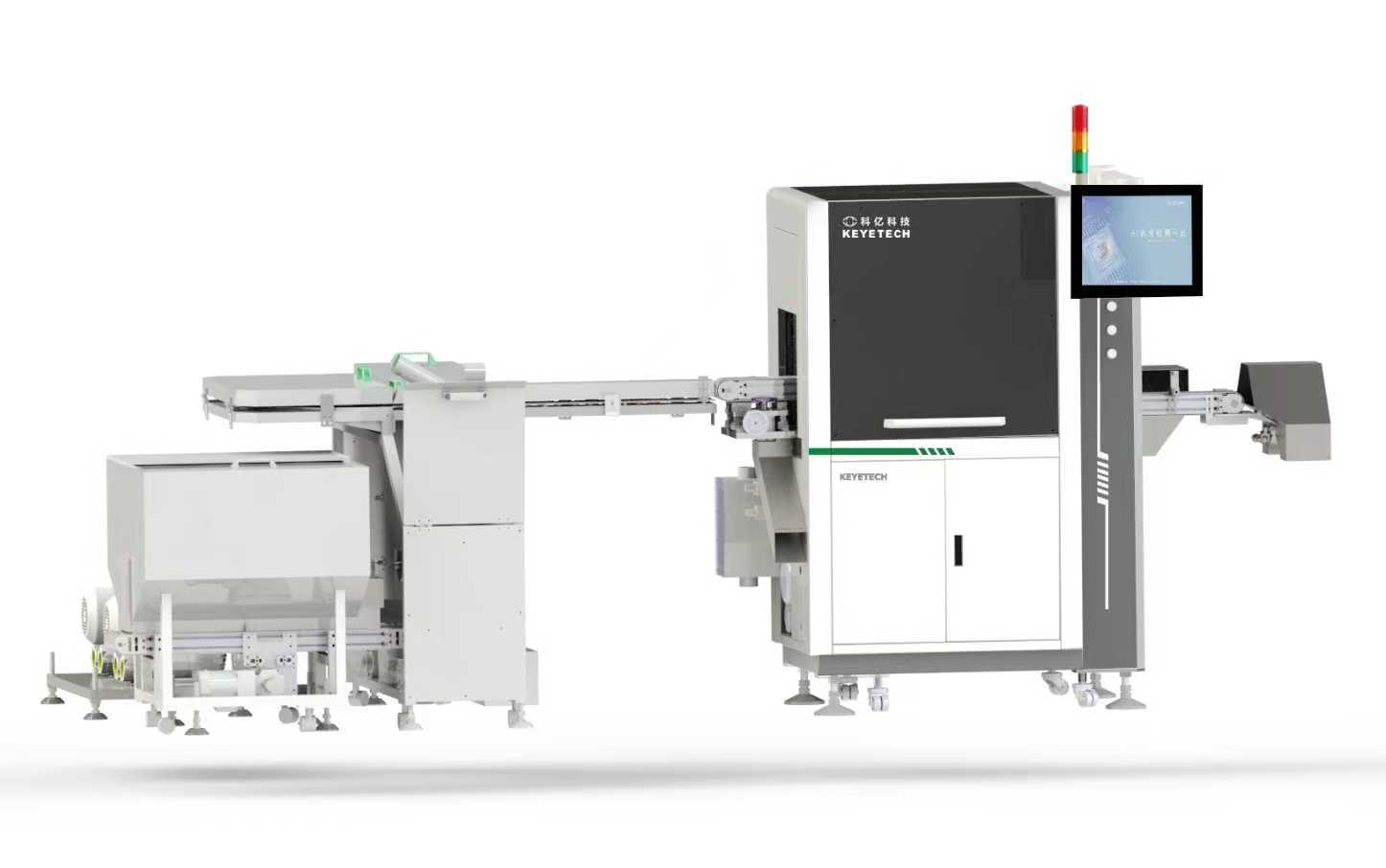

The choice of working mode is related to factors such as the adaptability of production scene equipment, inspection requirements, and costs. KeyeTech's fully automatic cap detection equipment can be equipped with low-speed, medium speed, and high-speed cap sorting machines offline, which can meet various production modes of enterprises.

Compatibility and adaptation of production lines: Some old production lines do not reserve online detection interfaces, making the transformation difficult. Choosing offline detection does not require changing the original production line structure and can flexibly adapt to various production lines;

High precision detection requirements: Offline mode can provide more sufficient detection time and stable environment, fundamentally ensuring the stability and reliability of detection accuracy;

Based on production volume: Suitable for small and medium-sized bottle cap manufacturers, offline mode does not waste production capacity and deployment is more flexible;

The AI visual inspection machine is not a "replacement for manual labor" tool, but an "intelligent partner" for production line personnel. For manufacturers in industries such as food, medicine, beverages, and alcoholic beverages, KeyeTech's offline inspection equipment is adapted to your specific scenario and helps you safeguard the quality of every product.

- Last:Why are more and more bottle manufacturers using fully automated inspection equipment to enhance their product competitiveness?

- Next:Are you still struggling with bottle cap detection? Manual checking has a high rate of missed inspections, and if we are not careful, unqualified products will enter the market, which will affect the brand reputation.