Are you still struggling with bottle cap detection? Manual checking has a high rate of missed inspections, and if we are not careful, unqualified products will enter the market, which will affect the brand reputation.

Date:2026-01-14 Views:22

The AI fully automatic cap inspection machine introduced to you today is a powerful tool specifically designed to help you solve this "quality control problem"!

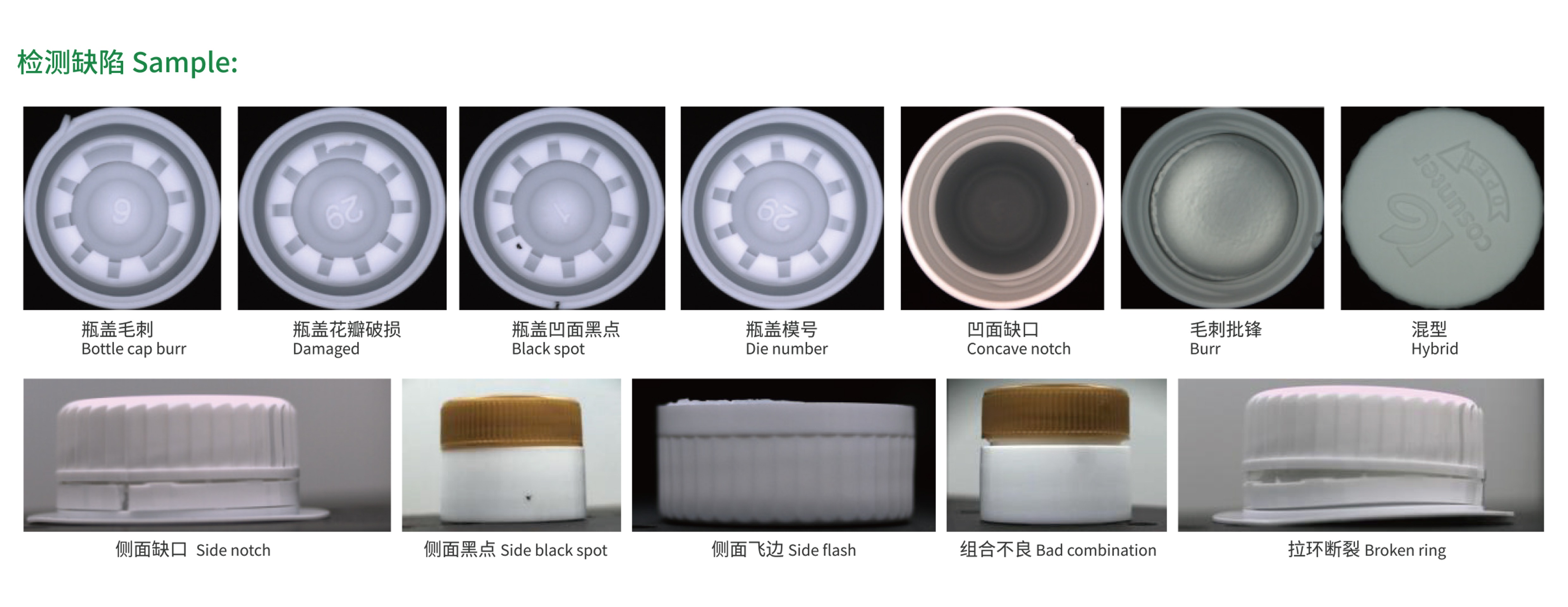

Firstly, accurate to the millimeter level to prevent any fish from escaping the net. KeyeTech's visual inspection machine, combined with self-developed high-definition cameras and customized light sources, forms an imaging system that can scan every detail of the cap 360°without blind spots - whether it is black spots, flying edges, or missing or broken gaskets, it can accurately identify them with a detection accuracy of up to 99.9%.

Secondly, the speed is fast enough to 'keep up with the production line', doubling efficiency without delaying production capacity. The detection speed can reach up to 2500 pieces per minute. And it is fully automated operation, without the need for dedicated personnel to monitor. One device can replace 3-5 inspection workers, saving a considerable amount of labor costs every month. The equipment money can be earned back in just a few months.

Thirdly, it has a certain range of compatibility. Paired with matching material handling equipment, the operation is more coordinated and smooth. When changing models, simply retrieve the appropriate solution from the system and the switch can be completed in 1 minute. Unlike some devices, changing the lid requires modifying the mechanical structure, which delays production for most of the day.

Fourthly, deep learning AI algorithms can continuously collect product defects, autonomously learn training samples, and make machines smarter as they use them, achieving a brain like thinking effect where what you see is what you get.

During the operation of a lid inspection machine, the bottle cap to be inspected reaches the feeding port of the cap inspection machine through the inspection machine, and the top surface of the bottle cap is sucked by the upper adsorption belt. The imaging system detects the plane of the bottle cap; Then, a comprehensive inspection is conducted through the lower adsorption belt and imaging system; Finally, the waste products are removed by blowing the valve and the finished products are counted.