one cap inspection machine can inspect different caps?

Date:2026-01-13 Views:26

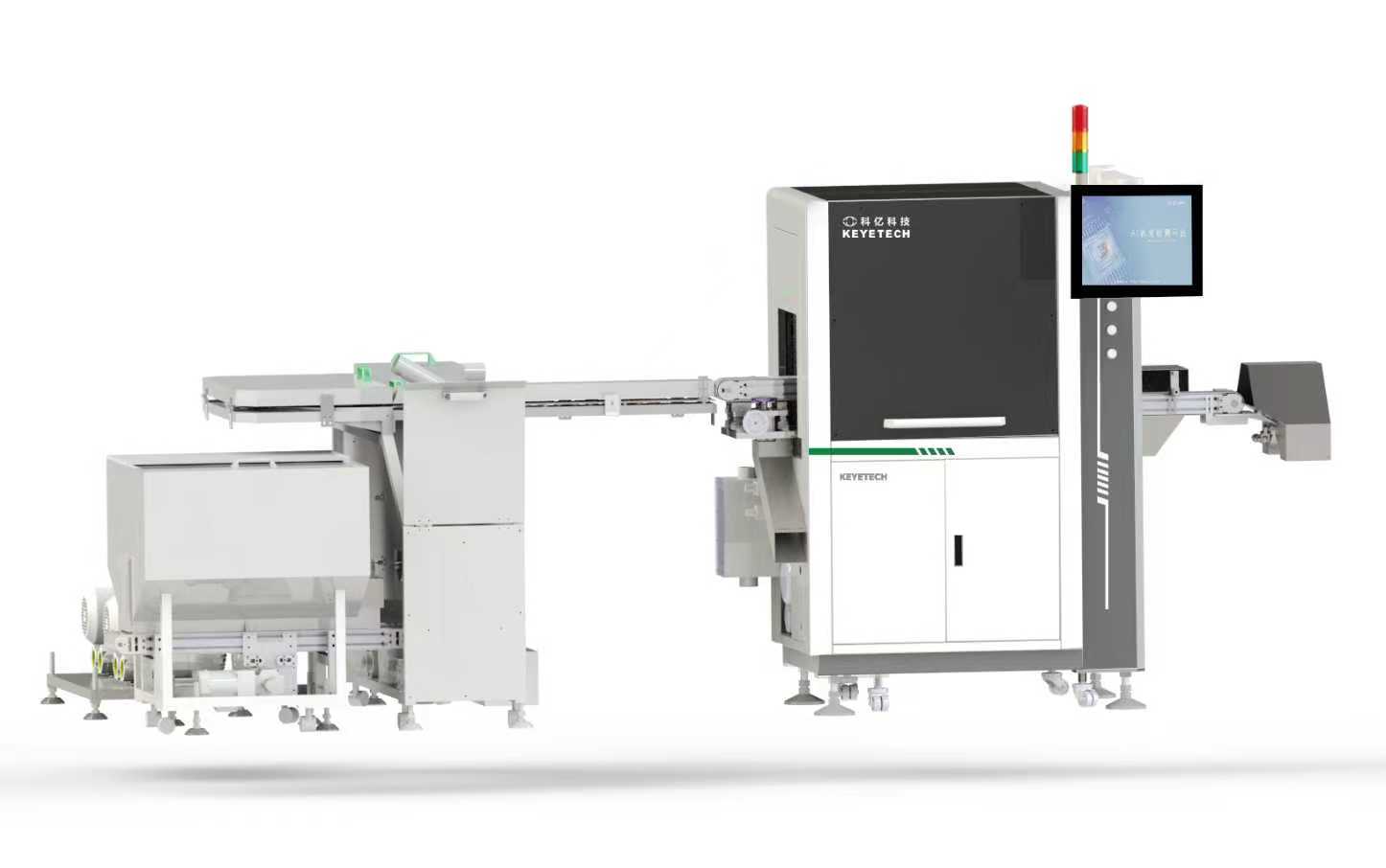

Compatibility is mainly limited by the holding bar of the cap feeding machine. The cap detection equipment of KeyeTech can be compatible with cap sizes with a height difference of no more than 1/3 and a diameter difference of less than 1/2.

After exceeding the compatibility range, it is necessary to match a cap feeding machine with the same specifications as the new bottle cap. The cap feeding machine transfering belt is the core component that controls the transportation of the cap, directly determining whether the cap can enter the detection area smoothly and orderly, ensuring that the cap does not jam or deviate; Secondly, it is necessary to adjust the cap separation wheel on the detection equipment to ensure that each cover passes through one by one and avoid stacking; Adjust the upper and lower positions of the adsorption belt according to the height of the new bottle cap (ensuring that the cap is stably adsorbed, not tilted during detection, and the camera can accurately capture images).

For manufacturers who need to produce multiple specifications of bottle caps, it is recommended that you purchase a inspection equipment to match different specifications of cap feeding machines. There is no need to purchase inspection equipment again. Simply replace the cap feeding machine and adjust the components to quickly switch between testing specifications, greatly reducing equipment procurement costs and reducing production line changeover time, thus improving overall production efficiency.

- Last:Are you still struggling with bottle cap detection? Manual checking has a high rate of missed inspections, and if we are not careful, unqualified products will enter the market, which will affect the brand reputation.

- Next:Advantages of Embedded Platforms and Disadvantages of Industrial Control Computers