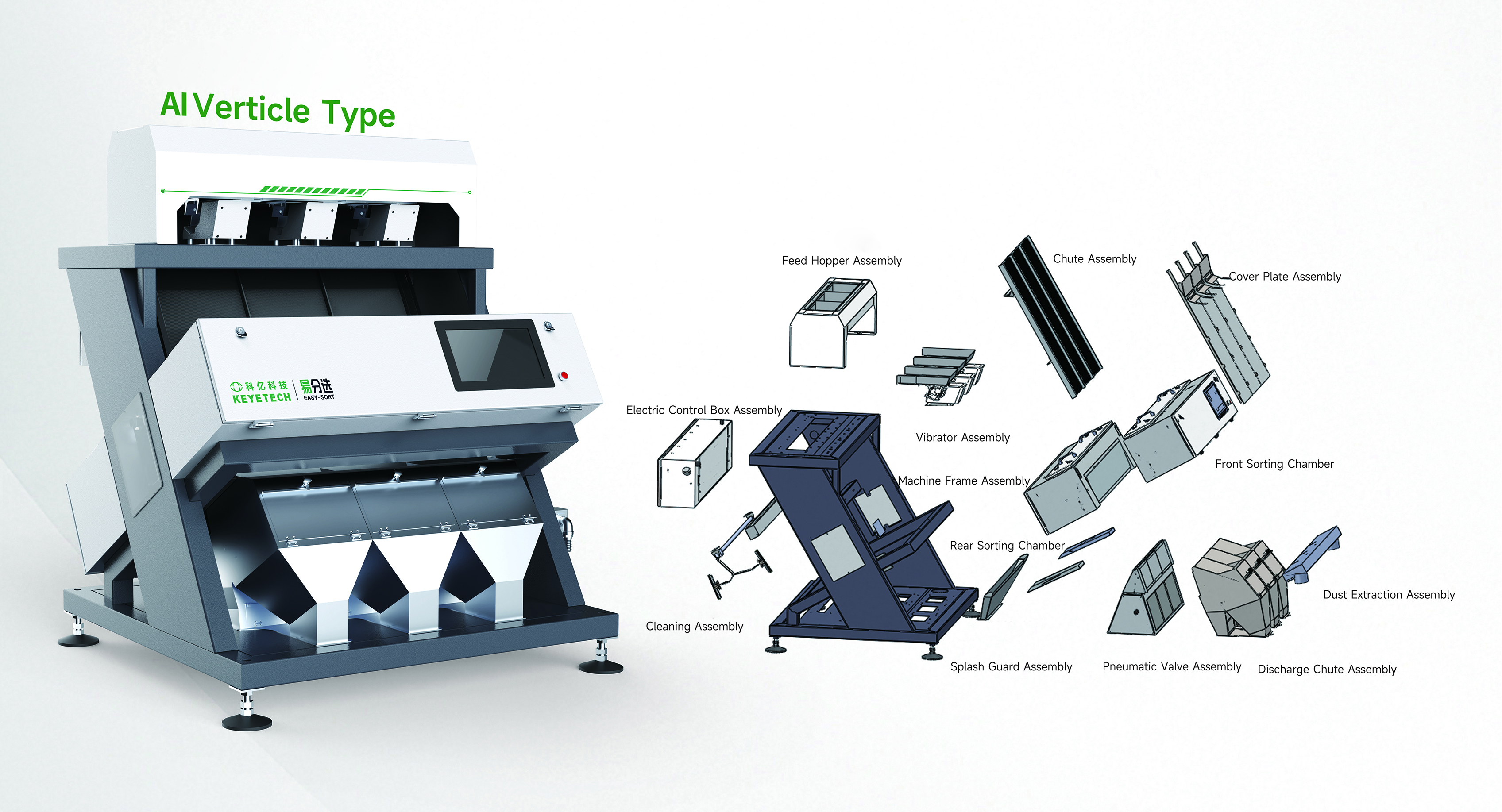

Vertical Type Sorter Structure and Working Principles of Each Component

Date:2025-12-27 Views:79

1.Feeding hopper: The inlet hopper which material enters the equipment, used to receive the material and control the feeding direction and initial material condition.

2.Vibrator: Generates vibration to evenly disperse the material and allow it to fall smoothly, preparing it for sorting.

3.Chute: Guides the material along a predefined path, ensuring directional and stable material conveyance.

4.Cover Assembly: Encloses the equipment area to prevent dust and material splashing.

5.Upper and Lower Vision Inspection Chambers: Equipped with cameras, lighting systems, and air nozzles to perform visual recognition of the material. This enables full-surface inspection to detect defects or specific features. Defective materials are precisely ejected by air jets from the nozzles.

6.Dust Cleaning Assembly: Removes dust from the equipment and inspection areas to ensure visual detection accuracy.

7.Air Nozzles: Spray compressed air based on detection signals to separate defective materials and execute the sorting action.

8.Dust Extraction System: Removes dust and light impurities inside the machine to maintain a clear inspection field of view.

9.Finished Product Hopper and Reject Hopper: Collect qualified and unqualified materials respectively after sorting, enabling classified collection.

10.Splash Guard Assembly: Prevents material splashing, keeps material on its intended path, and reduces material loss.

11.Electrical Control Cabinet: Controls the power supply and operating parameters of all machine components.

12.Machine Frame: Supports all components of the equipment, providing structural strength and ensuring overall stability.