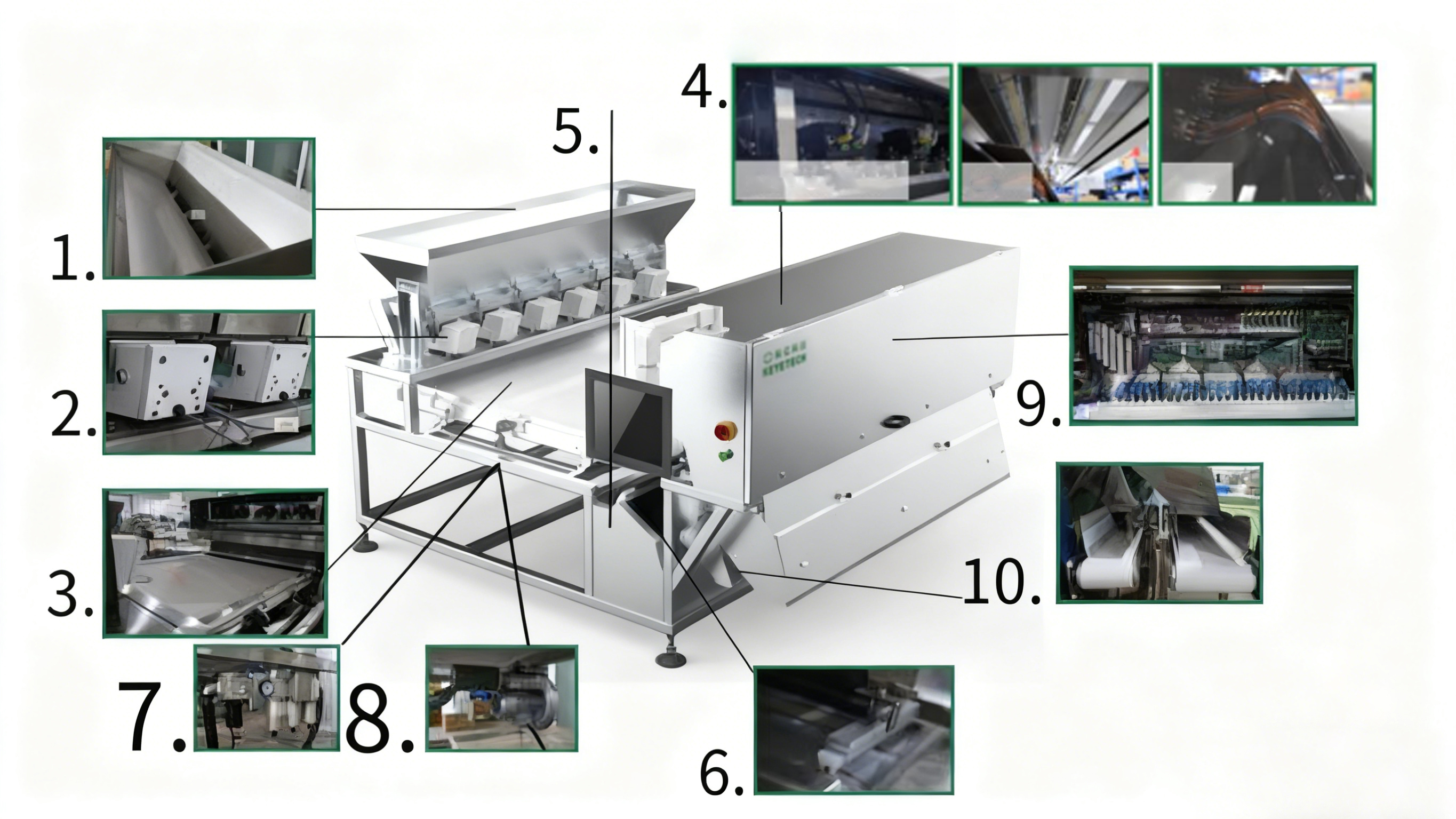

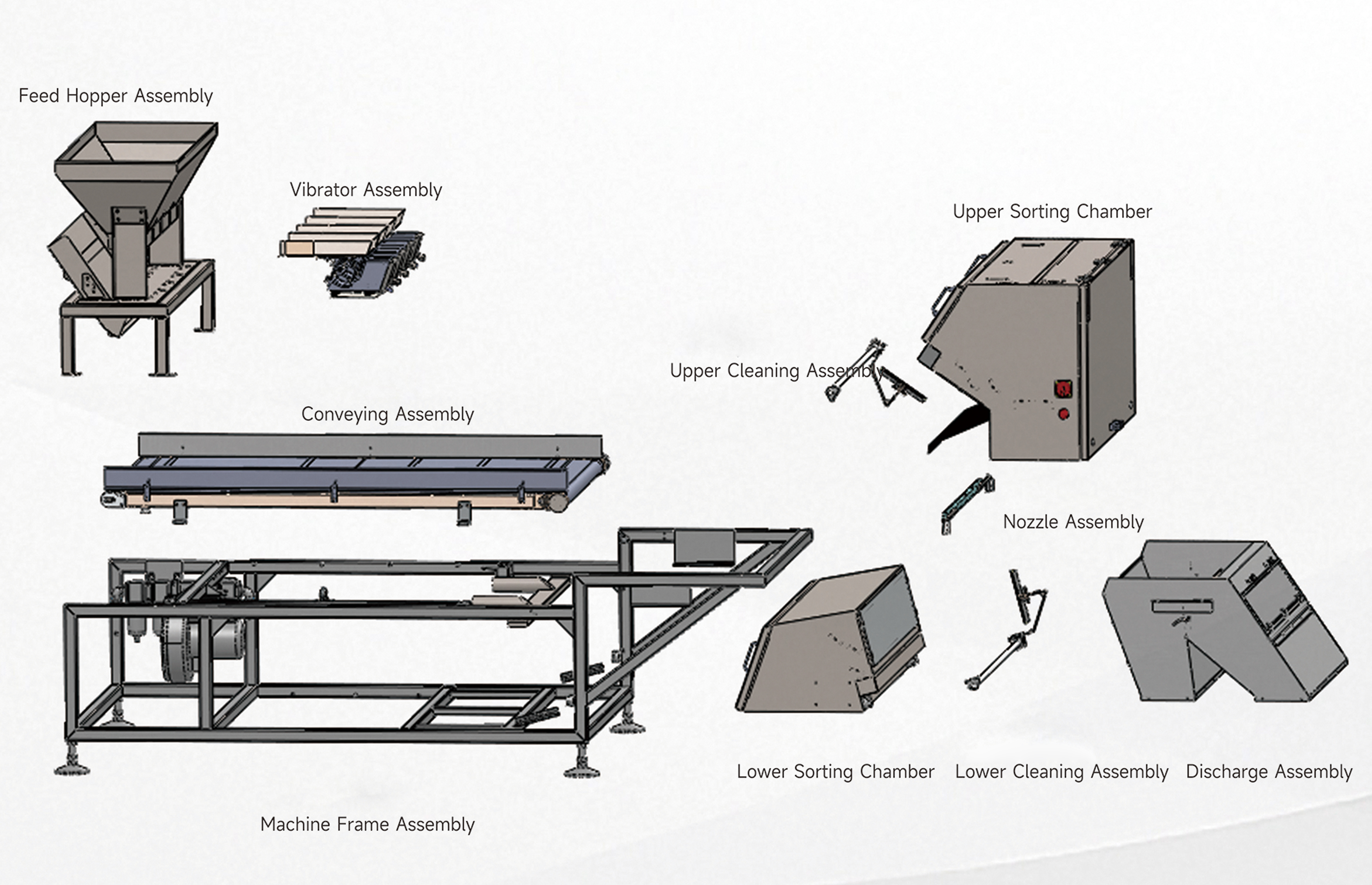

Belt Type Sorter Structure and Working Principles of Each Component

Date:2025-12-26 Views:75

1.Feeding Hopper: Receives and holds the incoming material.

2.Vibrator: Ensures even distribution and downward flow of the material.

3.Conveyor Belt: Primarily responsible for transporting the material.

4.Upper Vision Inspection Chamber: Equipped with a high dimensional HDR (Pro) camera, lighting source, ejector. The primary function is to capture images of the material, perform data calculations, and precisely eject defective material. The cooling fan is a critical auxiliary component for ensuring stable and accurate operation. It maintains proper airflow to dissipate heat generated during operation, preventing core components from failing due to overheating or environmental issues.

5.Lower Vision Inspection Chamber: Equipped with a high dimensional HDR (Pro) camera and a cooling fan.

6.Dust Cleaning Assembly: Primarily responsible for removing dust generated during the operation process.

7.Pneumatic Triplet: Regulates and controls the main working air pressure for the entire machine.

8.Air Blower: Mainly used for dust removal.

9.Electrical Control Cabinet: Manages the main power supply for the entire machine.

10.Discharge Outlet: Sorts and selects acceptive and rejective materials out through different discharge outlet.