What defects can a fully automatic glass bottle inspection machine detect?

Date:2025-12-10 Views:116

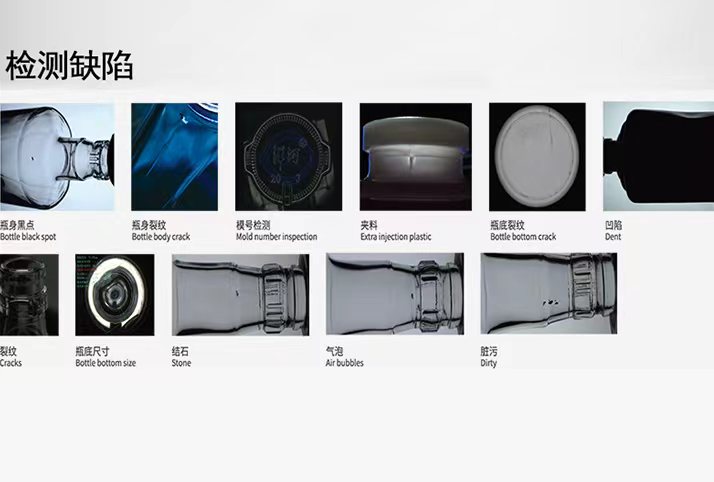

During the production process, glass bottles may develop defects of varying degrees due to the influence of raw materials, temperature, and production habits. Fully automatic glass bottle inspection machines mainly target three core types of defects: appearance, size, and internal defects, covering common problems throughout the entire production process.I. Surface defects Cracks, scratches, and dents on the bottle body, neck, and bottom, including fine cracks and deep dents. Air bubbles, sand particles, stones, and residual oil, stains, and watermarks on the glass surface. Bottle neck defects, such as deformed necks, burrs, missing material, and uneven sealing surfaces.II. Dimensional accuracy deviation The bottle height, diameter, and inner/outer diameter of the bottle mouth are out of tolerance and do not meet production standards. There are also issues with the roundness and perpendicularity of the bottle body, as well as uneven wall thickness. Deviations in the thread size and pitch of threaded bottles affect the subsequent sealing effect.III. Internal Impurities and Defects Foreign matter such as glass shards, dust, and fibers remaining inside the bottle. Layered defects and air bubbles inside the bottle wall affect light transmittance and structural strength.