What defects can a fully automatic bottle inspection machine detect? Why do these defects occur?

Date:2025-12-09 Views:114

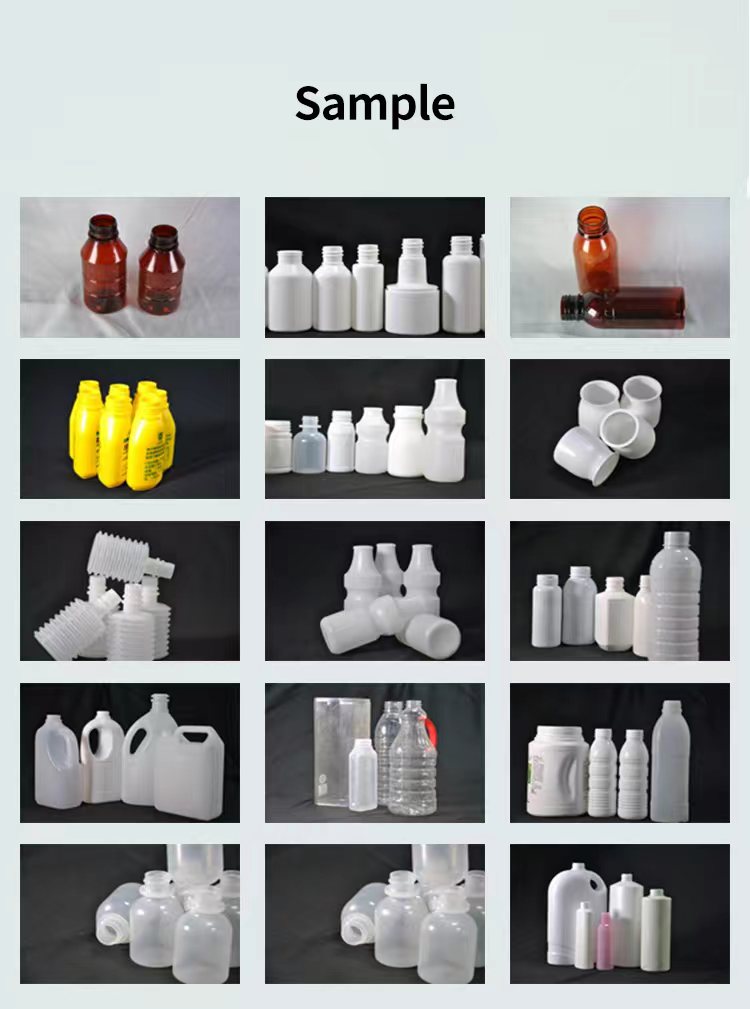

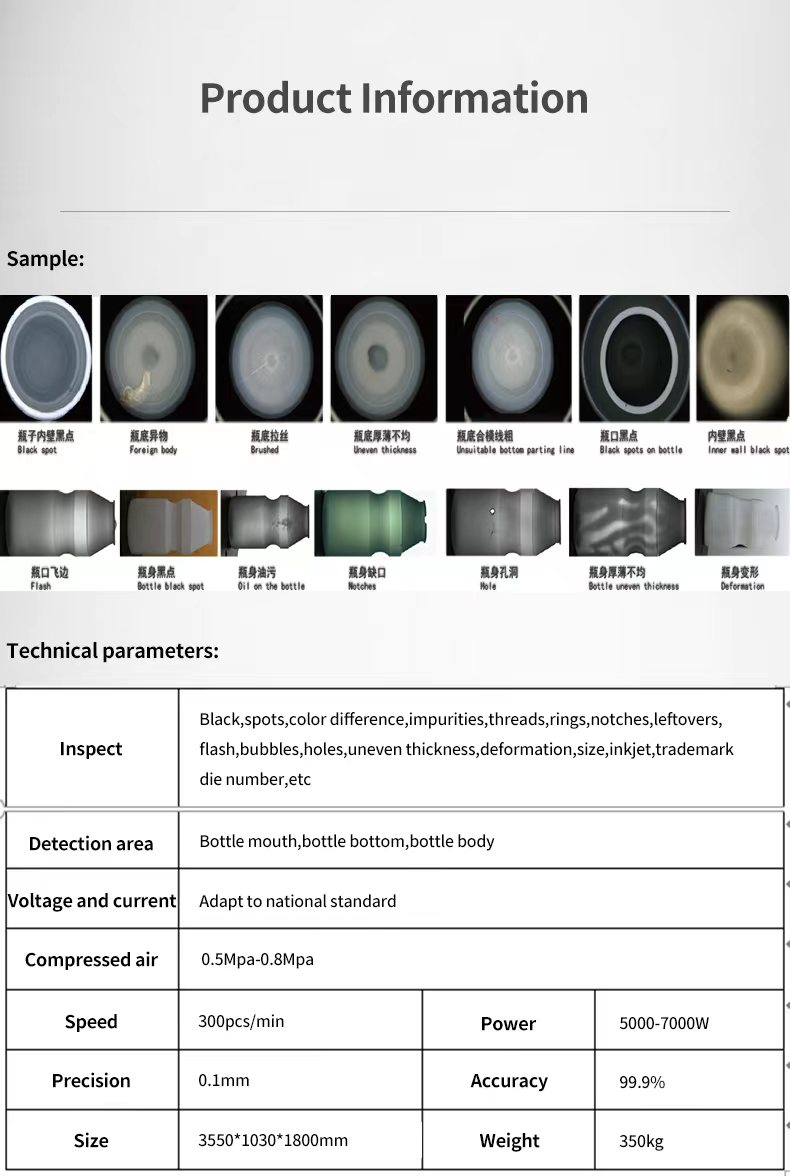

Fully automatic bottle inspection machines mainly focus on key defects such as bottle appearance, size, and sealing, which are mostly related to raw materials, production processes, or equipment conditions. Common issues that manufacturers need to test include: Appearance defects: Scratches, cracks, dents, bubbles, black spots, color differences on the bottle body, and misaligned, missing, or damaged labels. Dimensional deviations: Bottle height, bottle mouth diameter, and bottle wall thickness not meeting standards; uneven bottle mouth; damaged threads. Sealing issues: Poor bottle mouth seal, loose cap, leakage (for filled products). Impurities and foreign matter: Residual dust, metal shavings, plastic particles, and other contaminants inside the bottle. Molding defects: Bottle deformation, bottom bulges/dents, burrs at the bottle mouth, and significantly excessive parting lines.The main reasons for the defects:Raw material issues: Insufficient purity of plastic granules (containing impurities), excessive moisture, or unreasonable raw material formulation can easily lead to bubbles and color differences after molding. Improper molding process: Imbalance in temperature, pressure, and cooling time control during injection/blow molding can cause bottle deformation, uneven wall thickness, and cracks. Equipment malfunction: Mold wear and decreased precision can cause dimensional deviations; jamming of equipment conveyor components can cause scratches on the bottle and misaligned labels. Post-processing issues: Improper operation during filling and capping can lead to sealing problems; collisions during handling can cause dents and scratches. AI visual inspection equipment uses light, mechanics, electronics, computing, and software to collect, process, extract features, judge, and reject products based on differences in color, shape, and material. Compared to manual quality inspection, it has significant advantages in inspection quality and output. More and more manufacturers are choosing visual inspection equipment for production; AI quality inspection is an inevitable trend.