Application scenarios and equipment performance of printing inspection machines

Date:2025-12-04 Views:130

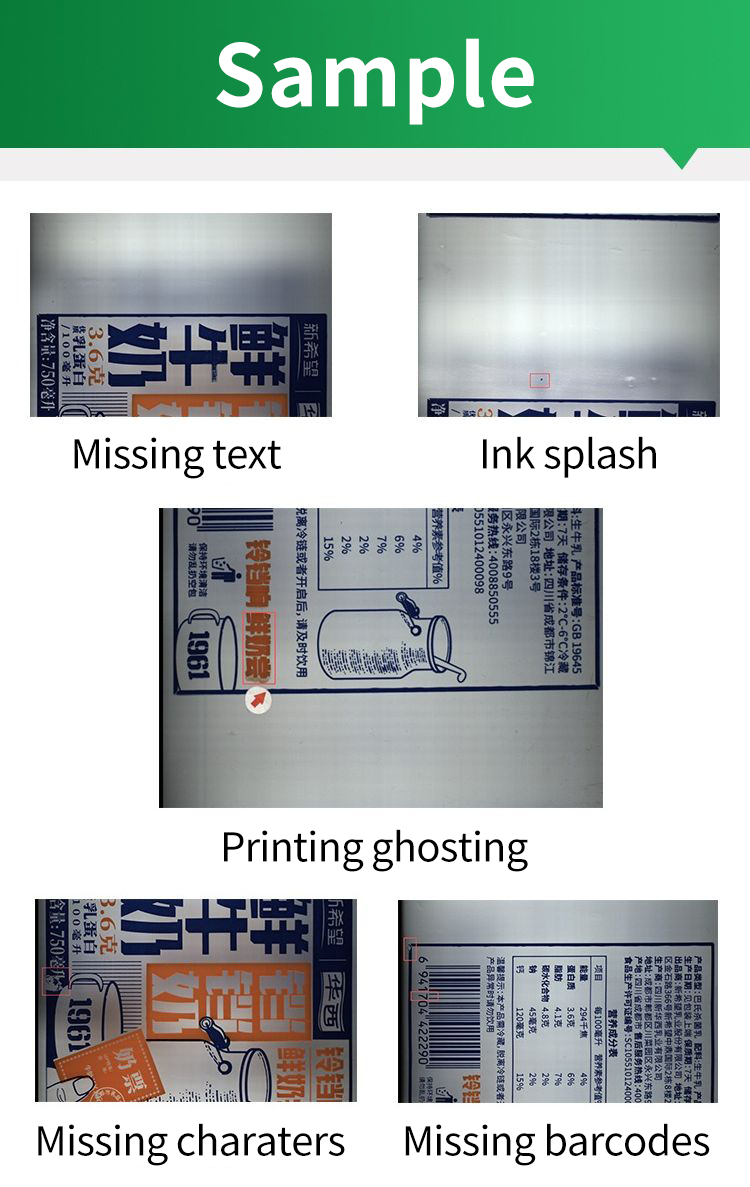

Automatic printing inspection machines are core equipment in modern printing production that ensures quality and improves efficiency. They are widely used in various printing scenarios and are directly related to production compliance, cost control, and market competitiveness.Main core application scenarios: Packaging Printing: Covering food, pharmaceutical, and daily chemical product packaging, with a focus on testing text clarity, pattern registration accuracy, color difference, and missing/misprinted areas to meet industry compliance requirements. Label Printing: Targeting small-sized, high-precision printed materials such as electronic labels and anti-counterfeiting labels, testing barcode readability and minor defects (such as pinholes and dirt spots).Necessity of equipment application: 1. High-precision detection: The equipment is equipped with an ultra-high-definition camera, which can accurately identify printing defects with an accuracy rate of 99.9%, meeting the stringent standards for packaging and printing quality in industries such as food and pharmaceuticals.2. Improve production efficiency:AI algorithms enable high-speed and efficient detection and sorting. Human-machine interaction allows for real-time display of detection status and feedback on printing defects on the screen; the equipment operates continuously and stably 24 hours a day.3. Reduce overall costs: Compared to manual inspection, this method reduces labor costs and minimizes losses and rework caused by incorrect or missed inspections, significantly improving the return on investment in the long run. Inspection standards include: missing characters, printing ghosting, misregistration, and ink splatter. Materials tested include: PET, PP, PS, etc. Inspection speed: 60-70 pieces/minute.