Visual inspection process and equipment working principle of transparent vaccine bottles

Date:2025-12-03 Views:134

Today, let me introduce the detection process of transparent vaccine bottles in AI visual inspection equipment:

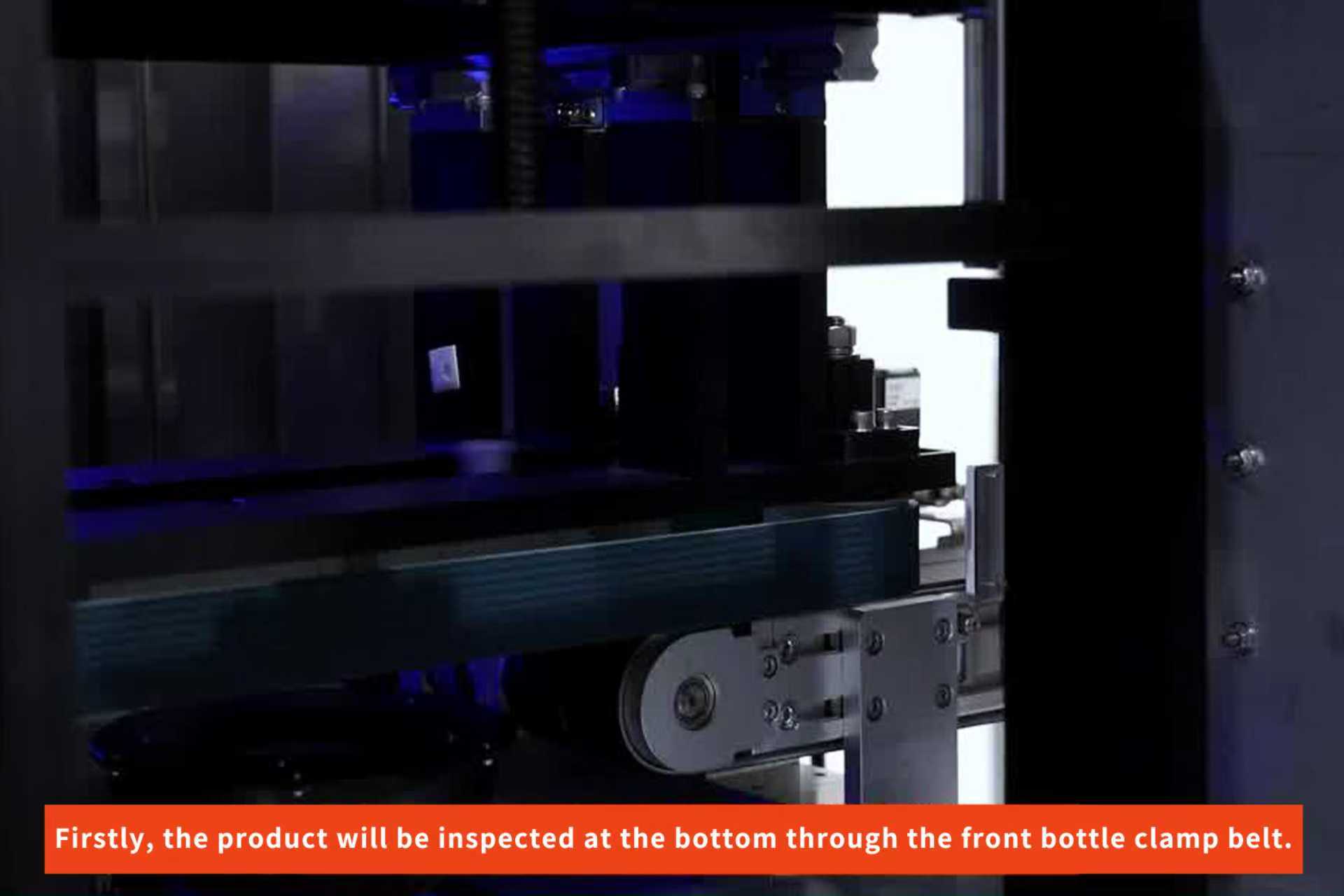

Firstly, the product will be inspected at the bottom through the front bottle clamp belt

Secondly, the top camera will detect the top of the product

3. Then, the light source system of the device will detect the surroundings of the product

4. Finally, the equipment accurately identifies finished and defective products, automatically eliminates them through valve blowing, and counts and divides them into boxes

Working Principle:

1. Industrial cameras perform high-precision recognition of products, and surface defects on products are exposed to natural lighting environments from multiple angles. Defects visible to the human eye can be detected.

2. Deep learning AI algorithms can quickly learn and simulate massive amounts of data with a small number of samples, significantly reducing the cost of manual training and learning management.

3. The human-computer interaction interface is simple and easy to operate, and the device detection results are displayed in real-time. OK and NG products can be viewed at a glance, and the detection data can be tracked.

Detection range: 360 ° all-round detection of bottle mouth, inner wall of bottle mouth, bottle bottom, and bottle body area

Defect detection: appearance defects such as black spots, color differences, impurities, threads, gaps, leftover materials, burrs, bubbles, etc

Detection speed: 300 pieces/minute

Stability of operation: 24-hour stable operation of the equipment