What is the difference between manual inspection and visual inspection?

Date:2025-12-30 Views:63

The main differences between the two lie in the following four aspects:

Detection Efficiency: Manual inspection is limited in output and low in production efficiency, making it unsuitable for large-scale industrial production. In contrast, AI-powered visual inspection systems enable one operator to manage multiple devices, allowing 24/7 continuous operation with high output and significantly improved production efficiency.

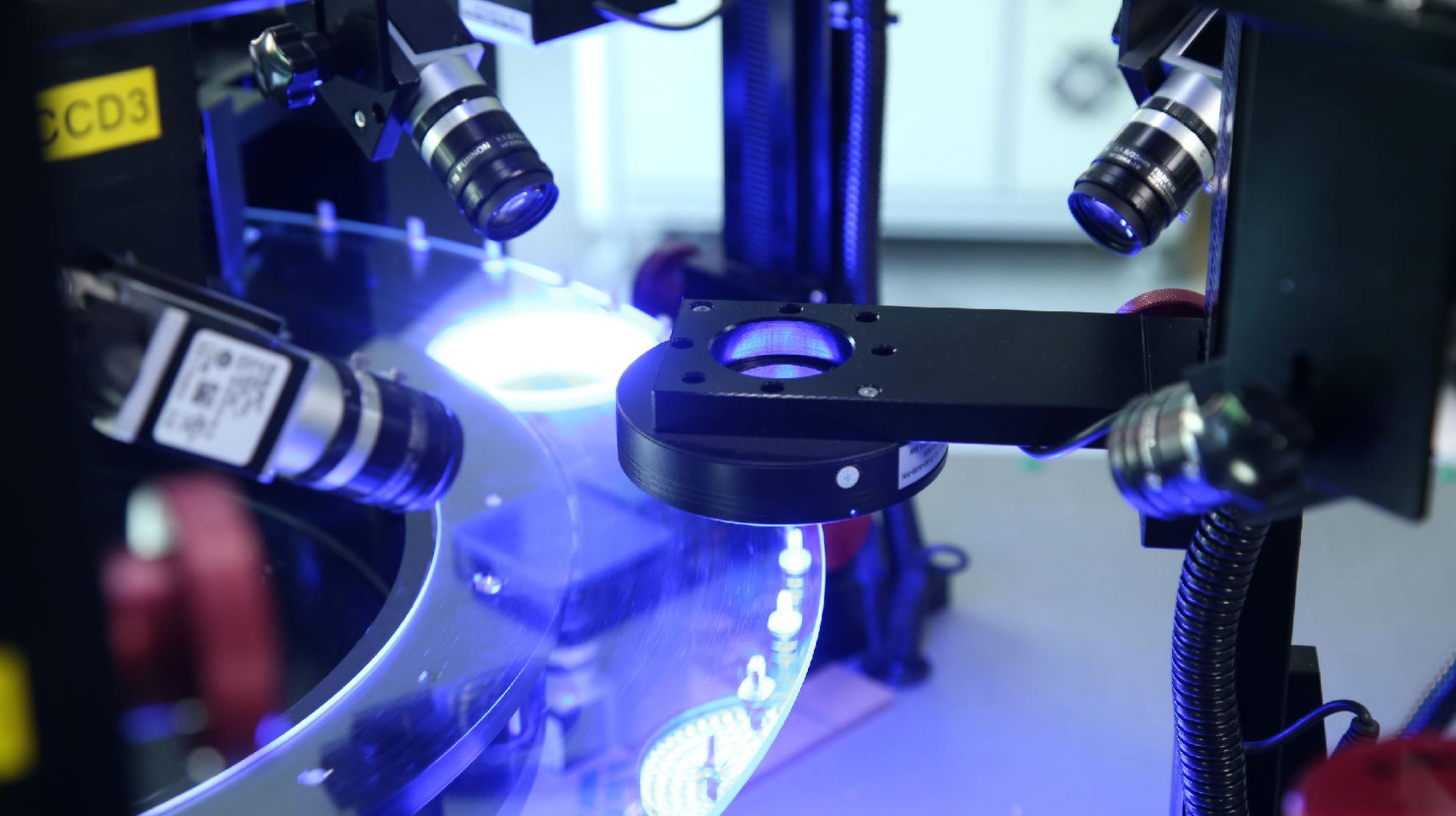

Standard Consistency: Manual inspection relies on experiential judgment, leading to inconsistencies in inspection standards among different personnel. Variations in evaluating color and defects often result in uneven product quality. Visual inspection systems, based on AI algorithms and high-definition cameras, achieve a detection precision of up to 0.1mm with an accuracy rate of 99.9%, ensuring uniform inspection standards.

High Accuracy: Human inspection is limited to what the naked eye can perceive, accurately identifying only visible defects. AI visual inspection systems, through advanced imaging technology, restore the true appearance and defects of products, achieving performance close to human-eye capability while also detecting defects beyond the range of human vision.

Stability: Manual inspection is susceptible to fatigue, emotional factors, and ambient lighting conditions, resulting in low stability. AI visual inspection systems are unaffected by environmental interference, offer strong adaptability, and maintain stable performance even during continuous operation.

In summary, AI visual inspection systems are characterized by high accuracy, efficiency, stability, and consistency. They help manufacturers save labor, improve efficiency, ensure quality, and reduce costs, representing an inevitable trend in the industry.