How important is the camera to image formation?

Date:2025-12-12 Views:115

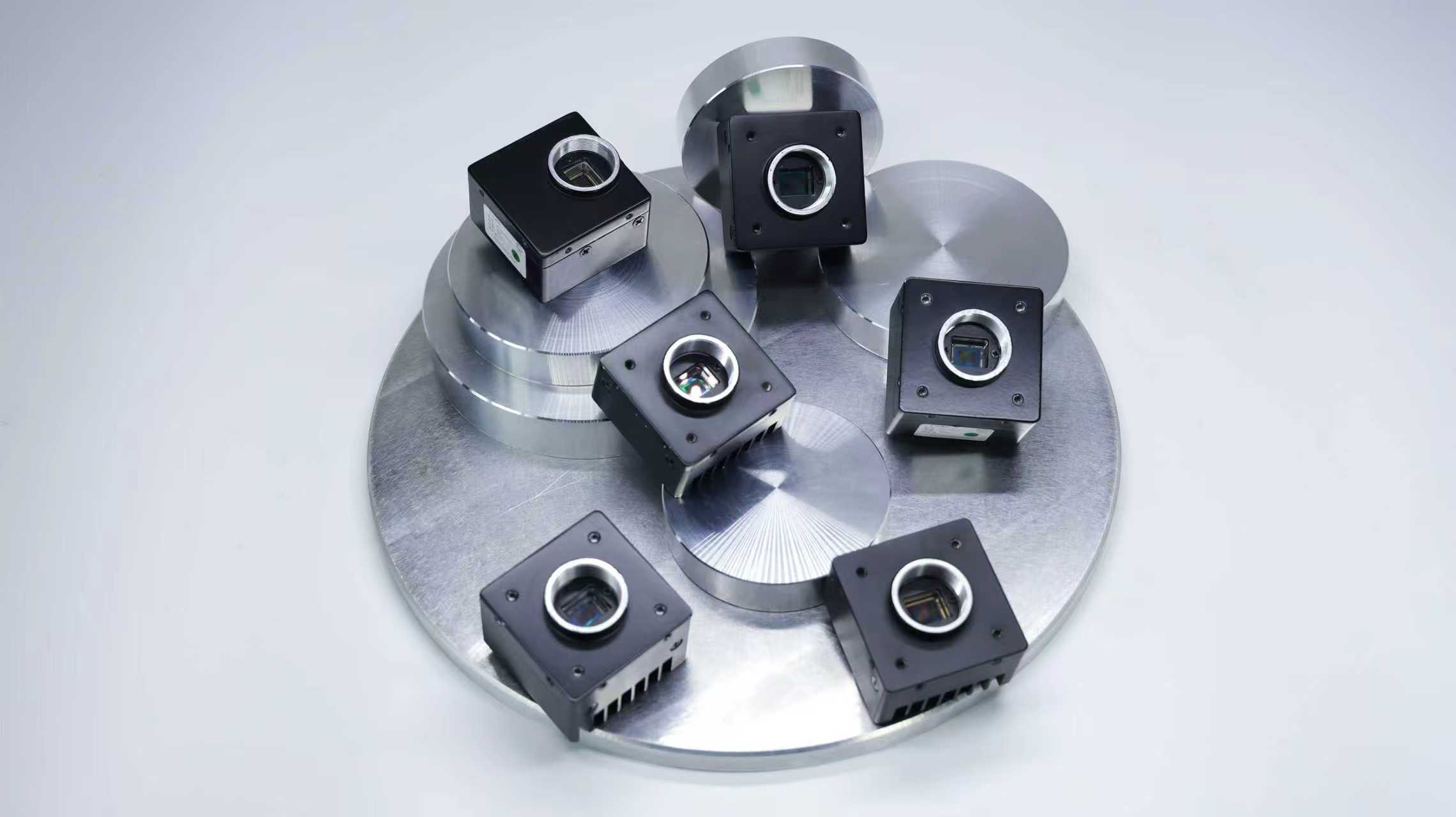

Cameras are the foundation of visual inspection, whose core logic is "imaging → analysis → decision-making." Camera performance directly determines the quality of the "imaging"—if the image is blurry or lacks detail, even the most advanced algorithms cannot extract effective features, ultimately leading to insufficient detection accuracy, high false negative and false positive rates, and system instability. Cameras must be precisely matched to inspection needs—selecting models based on four core requirements: "detection accuracy, detection speed, environmental conditions, and data transmission," rather than blindly pursuing high parameters. (For example, if a 3-megapixel camera suffices, there's no need for a 5-megapixel one.) Keye Technology's self-developed camera product line covers a full range of "intelligent imaging terminal matrices," including line scan cameras (4K/8K), area scan cameras (2MP/3MP/5MP, etc.), intelligent cameras, 2.5D cameras, and 3D cameras, meeting all imaging needs from standard to intelligent. High-definition lenses and master-level imaging lay the cornerstone of visual inspection equipment; only by accurately capturing product form can defects be identified.