What is the definition of AI visual inspection equipment? In which fields is it applicable? What are its core advantages?

Date:2025-12-06 Views:120

definition: AI visual inspection equipment is a device that uses light, mechanics, electricity, computing, and software to acquire, process, extract features, judge, and reject products based on differences in color, shape, and material.

Application areas:

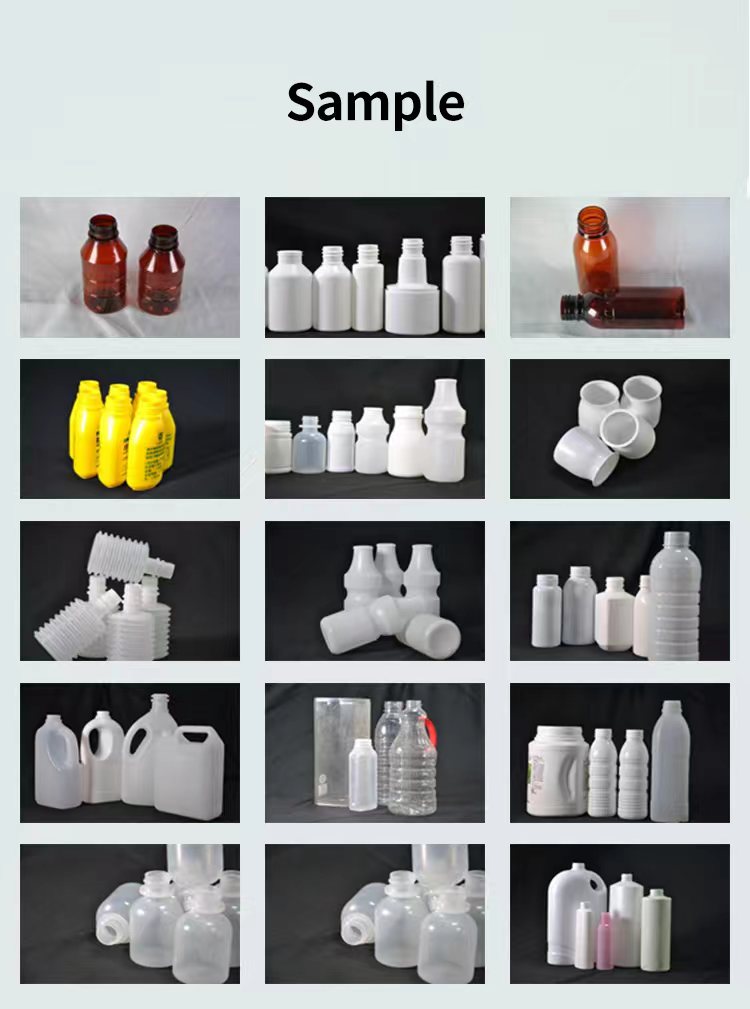

Packaging Inspection Detection of defects in outer packaging for industries such as food, beverages, dairy products, condiments, and pharmaceuticals, including black spots, deformation, gaps, burrs, dirt, poor labeling, and poor printing.Textiles: Defect detection in non-woven fabrics, homespun cloth, denim, embroidered fabrics, etc., such as broken threads, dyeing, foreign matter, unevenness, etc.print: Detection of printing defects in products such as eyebrow pencils, pens, capacitors, caps, and bottles, including missing text, ghosting, and misalignment of text and images.Electronic components: Defect detection for capacitors, VCHIP capacitors, etc., such as various appearance and dimensional defects on rubber surfaces, sleeves, leads, burrs, and rolled parts; as well as burrs, mixed dimensions, leakage, etc. on the appearance of horn capacitors. Core application advantages: Detection efficiency has been greatly improved It can work continuously for 24 hours without interruption, and the detection speed can be several times or even dozens of times that of manual detection, greatly shortening the detection cycle.The detection accuracy is stable and reliable. It can identify minute defects that are difficult to detect with the naked eye, avoiding subjective errors and fatigue misjudgments caused by manual inspection, and maintaining a stable accuracy rate over a long period of time.Significantly reduces overall costs: It reduces training and management costs, while avoiding rework and scrap losses due to misjudgment. In the long run, its cost-effectiveness far exceeds that of manual labor.Supports data-driven management: It automatically records data from each inspection, including the location, type, and quantity of defects, facilitating traceability and analysis and providing data support for production process optimization.Adapt to complex detection scenariosIt can cope with harsh environments such as high temperature, high pressure, and dust, as well as high-speed production lines, making the equipment more adaptable.