The main functions of the fully automatic IML inspection machine

Date:2025-11-28 Views:153

Q: What is the range of defects that can be detected by the IML inspection machine?

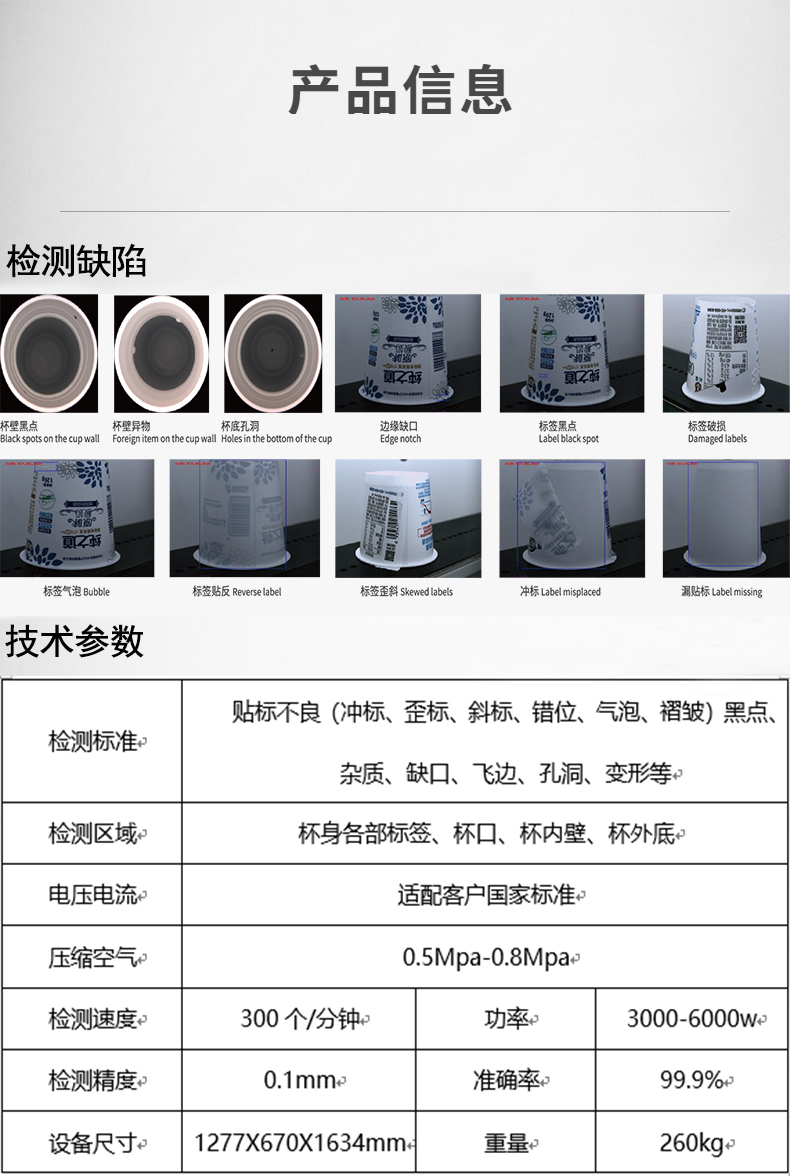

A: The equipment can detect label defects (such as punching, misalignment, slanting, misalignment, bubbles, wrinkles), black spots, impurities, gaps, burrs, holes, deformations, etc.

Q: What is the product range applicable to the IML inspection machine?

A: Suitable for 360 ° appearance inspection of yogurt cups, milk tea cups, etc.

Q: What performance advantages does the device have?

A: This detection machine is designed specifically for detecting label defects inside the mold. It uses an ultra clear camera and deep learning AI algorithm to detect label defects on various parts of the cup body (such as punch marks, crooked marks, oblique marks, misalignment, bubbles, wrinkles), and can synchronously detect black spots, burrs, deformations, and other defects in the cup mouth, inner wall, and outer bottom areas, quickly and accurately identifying and locating them. At the same time, the detection machine collects small sample defects and has super computing power. The software system displays the detection dynamics in real time, automatically eliminates defective products, and can be used immediately after startup, making it easy to operate.

The fully automatic In-Mold Labeling detection machine has the advantages of safety and reliability, high-speed and high-precision detection, simple and convenient operation, and long-term operation. It is an indispensable and important equipment on various in mold labeling container production lines. With one device, it can achieve multiple functions such as cost reduction and efficiency improvement, product quality improvement, and enterprise market competitiveness.